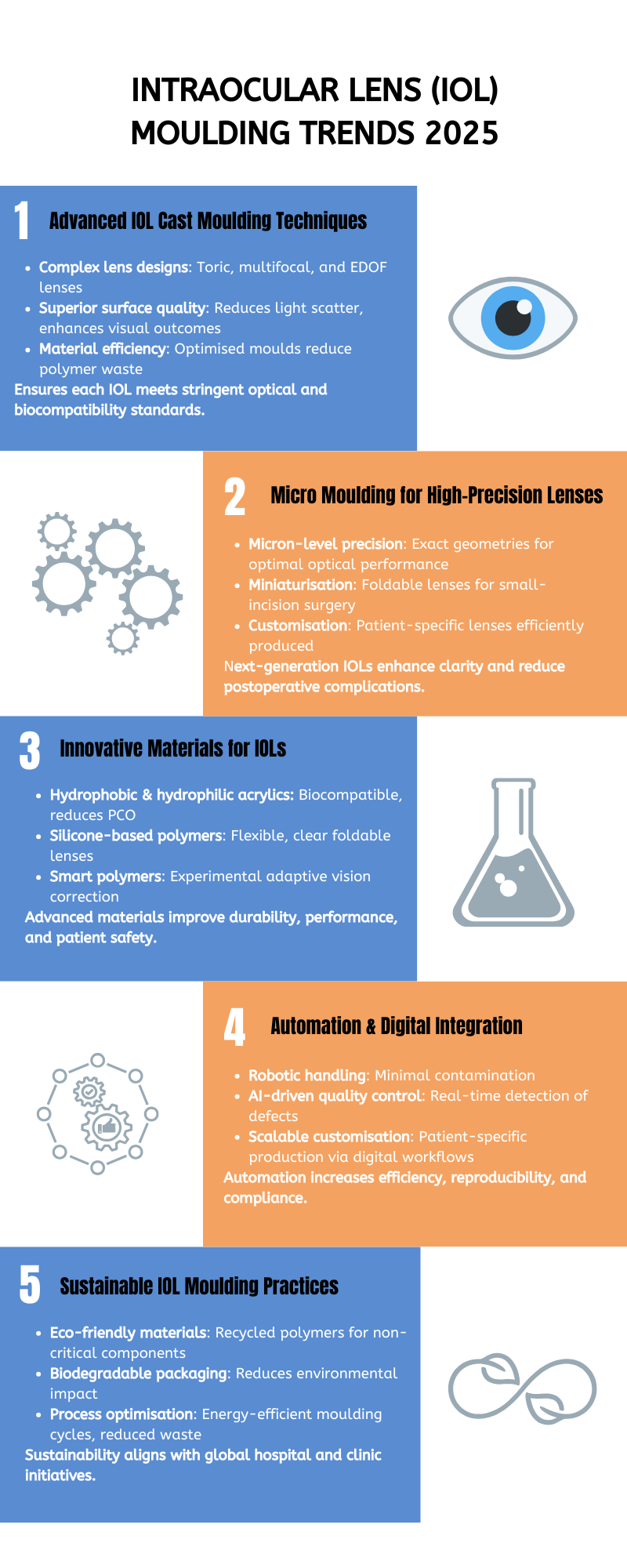

Intraocular Lens (IOL) Molding Trends 2025: Precision, Innovation, and Sustainability

The intraocular lens (IOL) industry is undergoing a technological transformation in 2025. With the global rise in cataract surgeries and refractive procedures, manufacturers are focusing on precision, advanced materials, customization, and sustainability in lens molding. This article examines the key IOL molding trends shaping ophthalmic care and medical device manufacturing this year.

1. Advanced IOL Cast Molding Techniques

Cast molding remains the gold standard for high-quality intraocular lens production. In 2025, manufacturers are leveraging:

- Complex lens designs: Toric, multifocal, and extended depth-of-focus (EDOF) lenses with precise geometries.

- Superior surface quality: Smooth lens surfaces reduce light scatter, enhancing visual outcomes.

- Material efficiency: Optimized mould designs minimize polymer waste, improving production cost-effectiveness.

These innovations ensure that each IOL meets stringent optical and biocompatibility standards, essential for safe and effective patient outcomes.

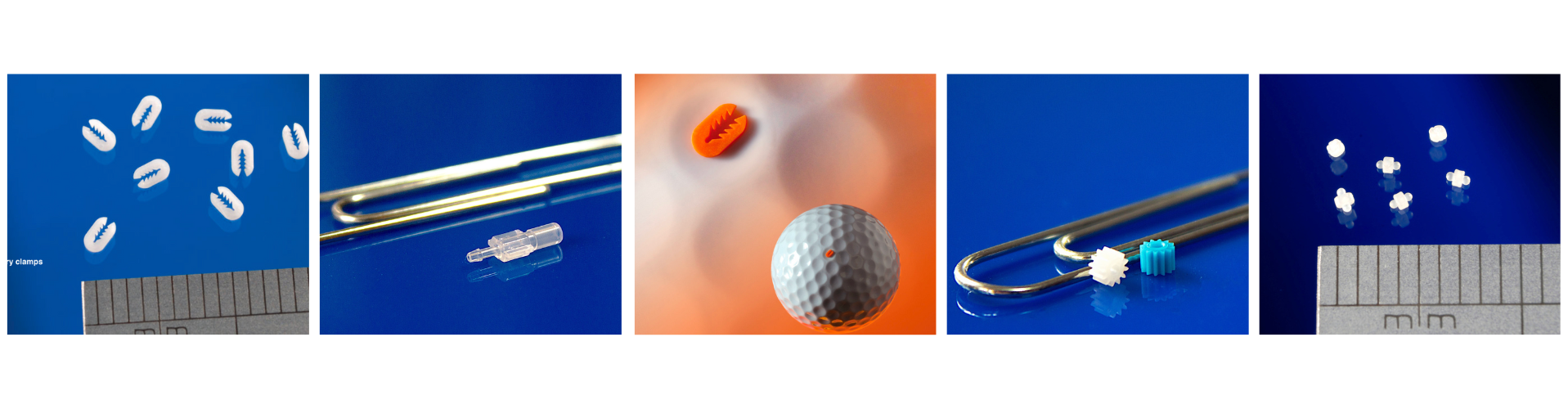

2. Micro Molding for High-Precision Lenses

Micro molding technology is revolutionizing lens production for minimally invasive cataract surgeries. Key benefits include:

- Micron-level precision: Producing lenses with exact geometries for optimal optical performance.

- Miniaturization: Foldable IOLs that can be implanted through small incisions, reducing surgical trauma.

- Customization: Patient-specific lenses can be manufactured efficiently, meeting unique anatomical requirements.

Micro molding allows the development of next-generation IOLs, enhancing visual clarity and reducing postoperative complications.

3. Innovative Materials for IOLs

Material advancements are critical for IOL performance. Leading polymers in 2025 include:

- Hydrophobic and hydrophilic acrylics: Ensuring biocompatibility and reducing posterior capsule opacification (PCO).

- Silicone-based polymers: Offering flexibility and optical clarity for foldable lenses.

- Smart polymers: Experimental materials that may allow adaptive vision correction in the future.

These materials improve lens durability, optical performance, and patient safety, positioning manufacturers at the forefront of ophthalmic innovation.

4. Automation and Digital Integration in IOL Production

Automation and Industry 4.0 technologies are transforming IOL manufacturing:

- Robotic handling: Ensures delicate lenses are handled with minimal contamination.

- AI-driven quality control: Machine vision systems detect surface defects, geometry deviations, and optical inconsistencies in real time.

- Scalable customisation: Digital workflows enable patient-specific IOL production without compromising quality.

These advancements increase manufacturing efficiency, reproducibility, and compliance with regulatory standards.

5. Sustainable IOL Molding Practices

Sustainability is a growing priority in medical device production:

- Eco-friendly materials: Recycled polymers for non-critical components.

- Biodegradable packaging: Reducing environmental impact in lens delivery.

- Process optimization: Energy-efficient moulding cycles and reduced material waste.

Sustainable practices align with hospital and clinic sustainability initiatives while maintaining high standards of patient care.

In 2025, intraocular lens molding is defined by precision engineering, micro molding, advanced materials, automation, and sustainability. These trends enable manufacturers to produce highly customised, safe, and effective IOLs that meet the growing demands of cataract and refractive surgeries worldwide. Companies embracing these innovations are poised to lead the ophthalmic device market, improving patient outcomes and advancing eye care technology.