The role of Overmolding in ergonomic and safe Drug Delivery devices

Overmolding, the process of molding one material over another to create a single, multi-material part, has become a pivotal manufacturing technique for modern drug-delivery devices. By combining rigid structural substrates with soft, pliable overmolded surfaces, designers can dramatically improve grip, tactile feedback, misuse resistance, and patient comfort, while meeting stringent biocompatibility and regulatory requirements.

Drug-delivery devices that patients operate themselves place unique demands on designers: they must be intuitive, comfortable for a wide range of users (including elderly or dexterity-impaired patients), and fail-safe under real-world use. Overmolding permits the integration of soft-touch interfaces, anti-slip features, and sealed interfaces without increasing assembly complexity, creating a route to both improved ergonomics and device safety. Reviews of the overmolding literature show rising interest in multi-material injection processes specifically for medical and wearable applications.

Overmolding: Processes and material considerations

Basic processes

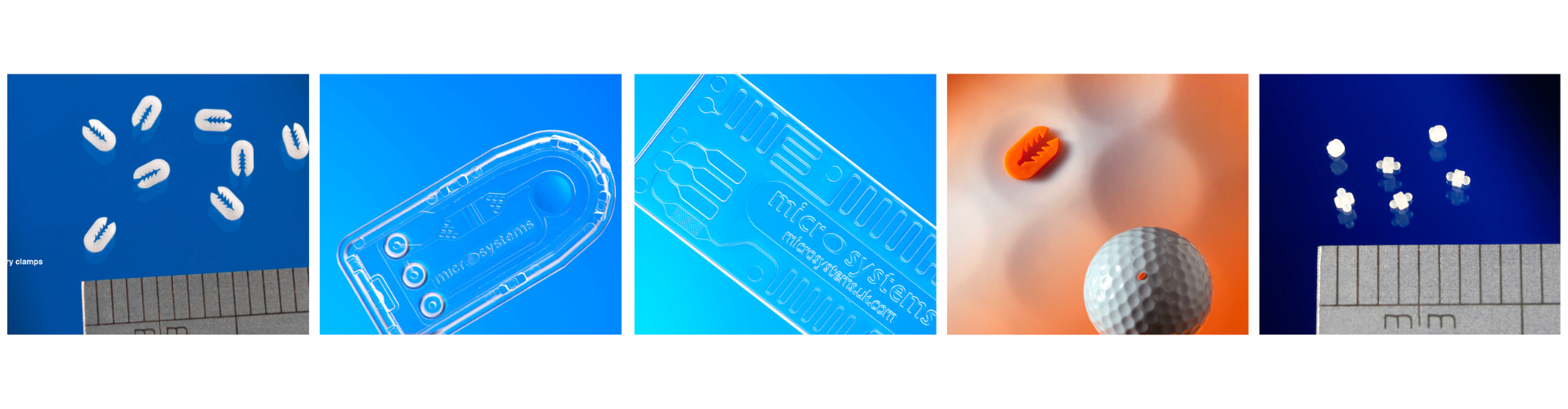

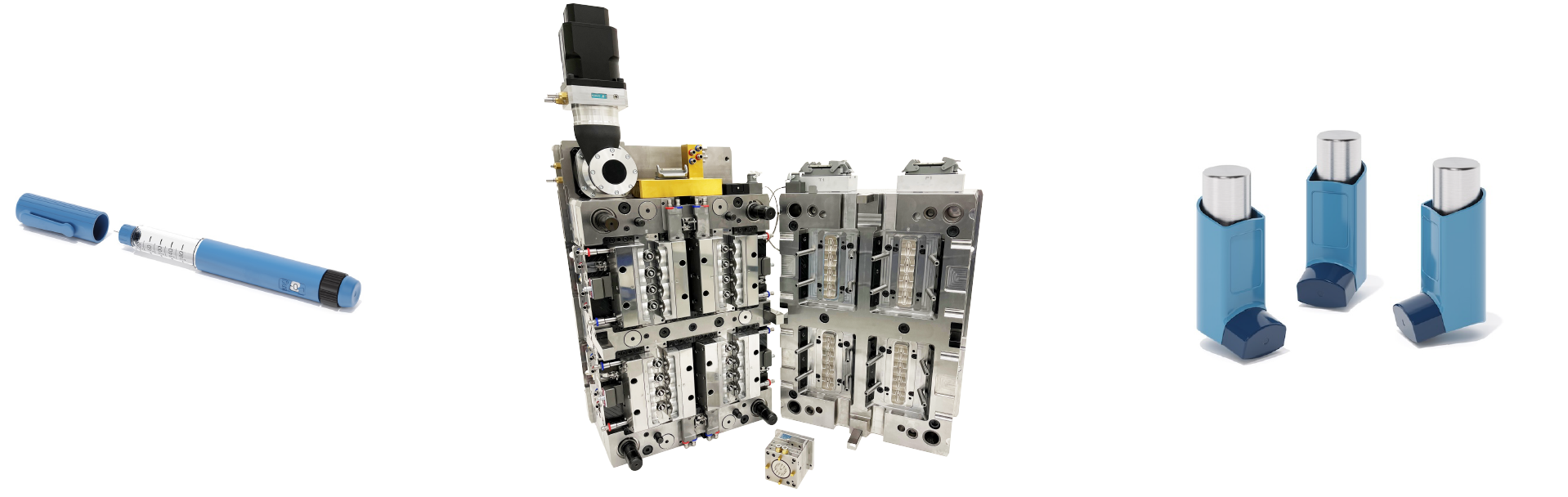

Overmolding typically uses a two-shot or sequential injection process in which a rigid thermoplastic substrate (for structural function) is first molded, then placed into a second tool cavity where a softer elastomer (thermoplastic polyurethane – TPU, thermoplastic elastomer – TPE, or liquid silicone rubber – LSR) is injected to form the overmold. Alternative approaches include insert molding and low-pressure liquid overmolding for electronics or delicate components. Recent reviews summarize advances in tooling, bonding strategies, and hybrid thermoset/thermoplastic systems.

Material selection

Material choices are driven by three competing needs: bonding, tactile performance, and regulatory (biocompatibility/chemical resistance). TPU and certain TPE grades form strong chemical bonds with substrates such as ABS, polycarbonate, and PBT, improving durability of the interface; LSR provides excellent skin feel and thermal stability but often requires mechanical interlocks rather than chemical adhesion when used on dissimilar substrates. Manufacturer guidance and technical reviews explain how substrate preparation, surface treatments, and mold design influence bond strength.

Biocompatibility and sterilization

Materials must withstand intended sterilization routes (gamma, ethylene oxide, autoclave if applicable) and show no adverse extractables/leachables. The selection of LSR, medical-grade TPU, or specially formulated TPEs is common in components that contact skin; all such selections should be validated with extractables/leachables testing appropriate to the device’s intended use.

Ergonomic advantages of Overmolding for drug delivery

Improved grip and control

Soft overmolded grips increase contact area and friction, enabling secure handling and better force transmission during tasks such as dose dialing and injection activation, especially important for older adults or users with reduced hand strength. Quantitative human factors studies demonstrate that improved tactile interfaces reduce errors in device manipulation and can shorten time-to-successful use in usability tests.

Tactile feedback and affordances

Overmolding allows designers to sculpt tactile cues (ribs, raised surfaces, soft click zones) directly into the device housing. These affordances support intuitive operation (for example, indicating orientation or the location of a trigger) and can be combined with visual cues for redundant signalling, a recognised human-factors best practice.

Reduced slip and improved patient confidence

Higher friction surfaces reduce slip risk during use with moist or sweaty hands, or when patients operate devices one-handed. This contributes to perceived safety and may improve adherence to prescribed regimens by lowering the effort and anxiety associated with device handling.

Safety, usability testing, and regulatory context

Human factors and usability engineering

Regulatory agencies (e.g., FDA, MHRA) expect human-factors engineering to be embedded in device development for self-administered products. Overmolding decisions should therefore be validated in formative and summative usability studies to ensure the changes reduce use-related hazards rather than introduce new confusions. Peer-reviewed human-factors frameworks and examples for injectable combination products provide methodologies for test planning and risk control.

Mechanical reliability and bonding failure modes

A critical safety concern is delamination of the soft overmold from the rigid substrate during handling, which could create pinch points, debris, or expose internal components. Design for bonding – selecting chemically compatible materials or providing mechanical interlocks (undercuts, knurls) – plus accelerated ageing and peel-force testing are essential parts of verification. Technical guidance on overmold bonding and industrial case studies outline test methods and acceptance criteria.

Cleaning, sterilization compatibility, and contamination control

Surface roughness and textured overmould regions improve grip but may retain contaminants. Designers must balance tactile geometry with cleanability and consider how sterilization or consumer cleaning routines affect material properties and microbial control. Validation plans should include worst-case soiling and cleaning cycles.

Design best practices for ergonomic and safe overmolded devices

- Early Human-Factors Input: Integrate user research before committing to final overmolded geometries – low-fidelity prototypes (3D printed substrates with silicone pads) speed iteration.

- Material compatibility mapping: Use material pairing charts to select substrate/overmould pairs with strong chemical affinity where possible; otherwise, design mechanical interlocks.

- Consider manufacturing tolerances: Account for shrinkage and thermal histories of both shots; consult molding specialists early to avoid flash or misregistration that degrades tactile features.

- Validation testing: Include peel tests, accelerated ageing, sterilization exposure, and full-scenario usability tests with representative user groups.

- Cleanability vs. texture trade-offs: Where infection control or residue removal is critical, prefer larger continuous soft zones with minimal deep micro-textures.

Application examples and case studies

Insulin pens and autoinjectors

Modern insulin pens commonly use overmolded soft grips and tactile dose-dials to improve comfort and reduce dose selection errors. Industry reports and device manufacturer patents document the use of overmolded gripping surfaces to assist one-handed operation. Such features are routinely evaluated in human-factors studies required for regulatory submissions.

Inhalers and nebuliser housings

Handheld inhalers benefit from soft overmolded mouthpiece grips and body surfaces that make correct orientation and actuation easier. Overmolding can also allow ergonomic contours that align with how users naturally hold the device, improving dose delivery consistency.

Wearable infusion and smart devices

Wearable patches and electronic drug-delivery modules increasingly combine overmolding with embedded electronics to create comfortable skin interfaces and sealed housings. Low-pressure overmolding and hybrid encapsulation methods are in the literature as approaches for protecting electronics while preserving soft contact surfaces.

Challenges and future directions

Advanced multi-material tooling cost: Two-shot tooling is capital-intensive; for low volumes, alternative prototyping approaches are still needed.

Recycling and sustainability: Multi-material parts are harder to recycle; future work may explore chemically compatible systems or design for disassembly to improve end-of-life handling.

Smart material integration: Integration of sensors within overmolded regions (pressure, capacitive touch) is an active area; process control must ensure sensor function is unaffected by overmold stresses.

Market trends and outlook

The medical overmolding market was valued at USD 1.8 billion in 2024 and is projected to reach USD 2.4 billion by 2030, growing at a compound annual growth rate (CAGR) of 4.4% during the forecast period from 2025 to 2030. This growth is driven by the increasing demand for advanced medical devices that require multi-material integration for enhanced functionality and patient comfort (stratviewresearch.com).

Similarly, the global drug delivery devices market was estimated at USD 432.4 billion in 2024 and is expected to reach USD 667.4 billion by 2030, growing at a CAGR of 7.5% from 2025 to 2030. This expansion reflects the rising adoption of advanced technologies for precise and efficient drug delivery Grand View Research.

Overmolding offers a compelling combination of ergonomic benefit and manufacturability for patient-facing drug-delivery devices. When paired with rigorous human-factors engineering, appropriate material selection, and thorough validation (mechanical, biocompatibility, sterilization, and usability), overmolded surfaces can materially improve device safety, usability, and patient adherence. Designers should treat overmolding not simply as an aesthetic finish but as an engineering tool that bears directly on risk-control, regulatory strategy, and the patient experience.

Key references

Aliyeva, N., Recent developments on the overmolding process for thermoset- and thermoplastic-based composite systems, Composites Part B (review).

Protolabs, Designing for overmolding – material bonding guidance and tips.

MRP Corporation, Benefits and challenges of silicone overmolding for medical devices (technical brief).

Holden, R. J., Human Factors and Ergonomics Methods for Pharmacy and Medication Use, Patient Safety Literature (review).

Towns, J. K., Human factors studies for injectable combination products, Regulatory Human Factors literature.

Formlabs (industry case study), Overmoulding and insert moulding for wearable electronics.