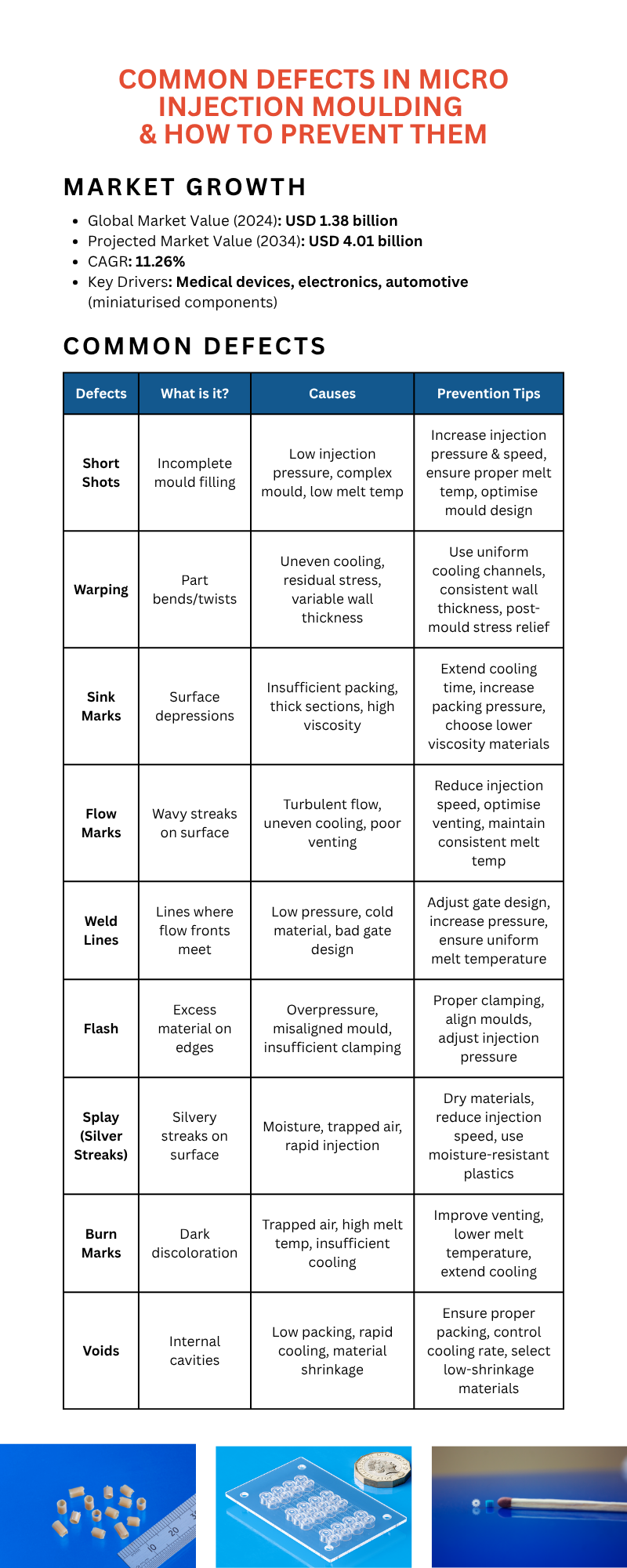

Common defects in Micro Injection Molding & how to prevent them

Micro injection molding is a precision manufacturing process used to produce small, intricate plastic components. However, due to the complexity and scale of these parts, various defects can arise, impacting product quality and performance. Understanding these defects and implementing preventive measures is crucial for maintaining high-quality standards in micro molding operations.

Market trends and growth of Micro Injection Molding

The global micro injection molding market has been experiencing significant growth, driven by the increasing demand for miniaturized components across various industries. In 2024, the market was valued at approximately USD 1.38 billion and is projected to reach USD 4.01 billion by 2034, expanding at a compound annual growth rate (CAGR) of 11.26% (Precedence Research). This growth is particularly evident in sectors such as medical devices, electronics, and automotive, where there is a rising need for small, precise, and intricate components

1. Short Shots

Definition: A short shot occurs when the mould cavity is not completely filled, leading to incomplete parts.

Causes:

Insufficient injection pressure or speed.

Inadequate heating of the plastic material.

Complex mold designs with thin walls or distant cavities.

Prevention:

Enhance injection pressure and speed to ensure complete filling.

Ensure the plastic material is adequately heated for optimal flow.

Simplify mould designs or incorporate multiple injection points to facilitate material flow.

2. Warping

Definition: Warping is the deformation of a part due to uneven cooling, causing it to bend or twist.

Causes:

Uneven cooling rates across the part.

Variations in wall thickness.

Residual stresses from the molding process.

Prevention:

Implement uniform cooling channels to ensure consistent temperature distribution.

Design parts with uniform wall thickness to promote even cooling.

Apply post-molding treatments to relieve internal stresses.

3. Sink Marks

Definition: Sink marks are depressions on the surface of a part, typically occurring over thicker sections.

Causes:

Inadequate packing pressure during the injection phase.

Insufficient cooling time.

High material viscosity.

Prevention:

Increase packing pressure to compensate for material shrinkage.

Extend cooling time to allow for complete solidification.

Use materials with lower viscosity to enhance flow characteristics.

4. Flow Marks

Definition: Flow marks are visible lines or streaks on the surface of a part, resulting from variations in material flow.

Causes:

Differences in cooling rates during injection.

High injection speed leading to turbulent flow.

Inadequate venting in the mold.

Prevention:

Optimize injection speed to reduce turbulence.

Design molds with proper venting to allow air escape.

Maintain consistent melt temperature to ensure uniform flow.

5. Weld Lines

Definition: Weld lines are visible lines where two flow fronts meet but fail to fuse properly, leading to weak spots.

Causes:

Low injection pressure or speed.

Cold material temperatures at the meeting point.

Poor gate design or placement.

Prevention:

Increase injection pressure and speed to promote better fusion.

Ensure uniform material temperature throughout the molding process.

Optimize gate design and placement to facilitate smooth flow and fusion.

6. Flash

Definition: Flash refers to excess material that seeps out between mold parts, creating unwanted thin edges.

Causes:

Excessive injection pressure.

Worn or misaligned mold components.

Inadequate clamping force.

Prevention:

Adjust injection pressure to appropriate levels.

Regularly inspect and maintain mold components to ensure proper alignment.

Apply sufficient clamping force to prevent material leakage.

7. Splay (Silver Streaks)

Definition: Splay appears as silvery streaks on the surface of a part, often caused by moisture or gas in the material.

Causes:

Moisture in the plastic material.

High injection speed causing rapid gas expansion.

Inadequate drying of hygroscopic materials.

Prevention:

Dry plastic materials thoroughly before processing.

Reduce injection speed to minimize gas entrapment.

Use moisture-resistant materials when possible.

8. Burn Marks

Definition: Burn marks are dark spots or discolorations on parts, resulting from overheating.

Causes:

Trapped air or gas in the mold cavity.

High melt temperature.

Insufficient cooling time.

Prevention:

Improve mold venting to allow trapped air to escape.

Lower melt temperature to reduce the risk of overheating.

Extend cooling time to ensure complete solidification.

9. Voids

Definition: Voids are internal cavities within a part, leading to reduced strength and integrity.

Causes:

Inadequate packing pressure.

Rapid cooling causing material contraction.

Improper material selection.

Prevention:

Apply adequate packing pressure to fill all areas of the mold.

Control cooling rates to prevent rapid contraction.

Select materials with appropriate shrinkage characteristics.

Addressing common defects in micro injection molding requires a comprehensive understanding of the process and proactive measures. By identifying potential issues early and implementing preventive strategies, manufacturers can enhance product quality, reduce waste, and improve overall efficiency. Regular monitoring, maintenance, and optimisation of moulding parameters are essential for achieving consistent, high-quality results in micro injection molding operations.

References

Chaciński, T. (2021). Common defects in injection molding of plastic products and their prevention. Journal of Materials Engineering and Performance.

Wang, X. (2013). Research on the reduction of sink mark and warpage in injection molding. Polymer Testing.

Zhang, J., Yan, D., Peng, L., & Huang, X. (2024). Dimensional analysis theory and molecular dynamics simulation of polypropylene melt flow during injection molding process.

Li, X., Mi, H., & Dong, B. (2024). A review of research progress on the minimization of weld lines in injection molding. Polymer Testing.