Ophthalmics

ULTRA PRECISION MOLDING & TOOLING FOR CONTACT LENSES AND OPTICAL DEVICES

Micro Systems specializes in ultra-precision mold design, manufacturing, and injection molding for advanced optical applications. Our capabilities range from high-volume, multi-cavity optical molds with tight toricity tolerances to single-cavity micro Fresnel lenses with nanometer-scale features.

We provide end-to-end solutions for:

-

Contact lens molding

-

Contact lens blister packaging

-

Intraocular lens (IOL) tooling

-

Custom optical-grade polymer components

With expertise in high-accuracy optical tooling and micro-molding, we support from prototyping to scalable production under ISO 13485 & ISO 9001 standards.

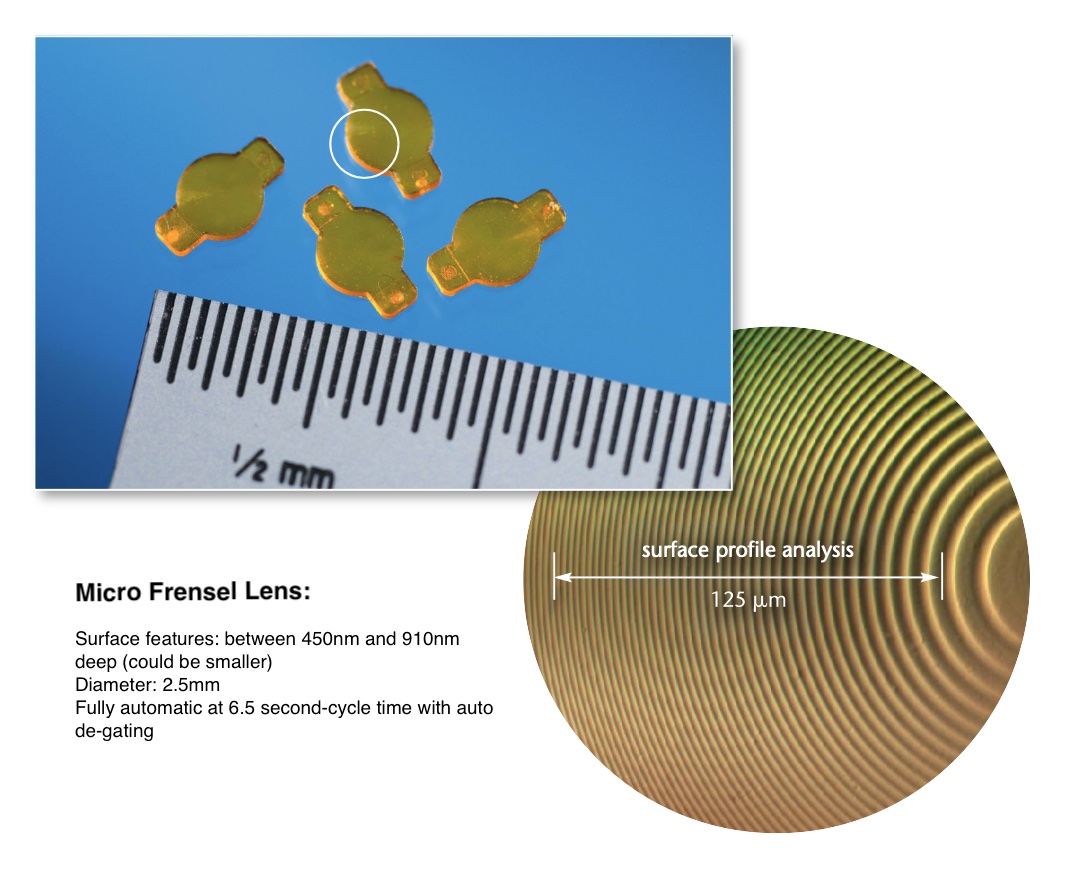

MICRO FRESNEL LENS

Micro Systems manufactures 2.5 mm micro Fresnel lenses using a fully automated 4-cavity mold with a 6.5-second cycle time and auto degating. Lens surface features range from 450 nm to 910 nm, with sub-450 nm capability—ideal for optical micro molding and high-precision photonic components.

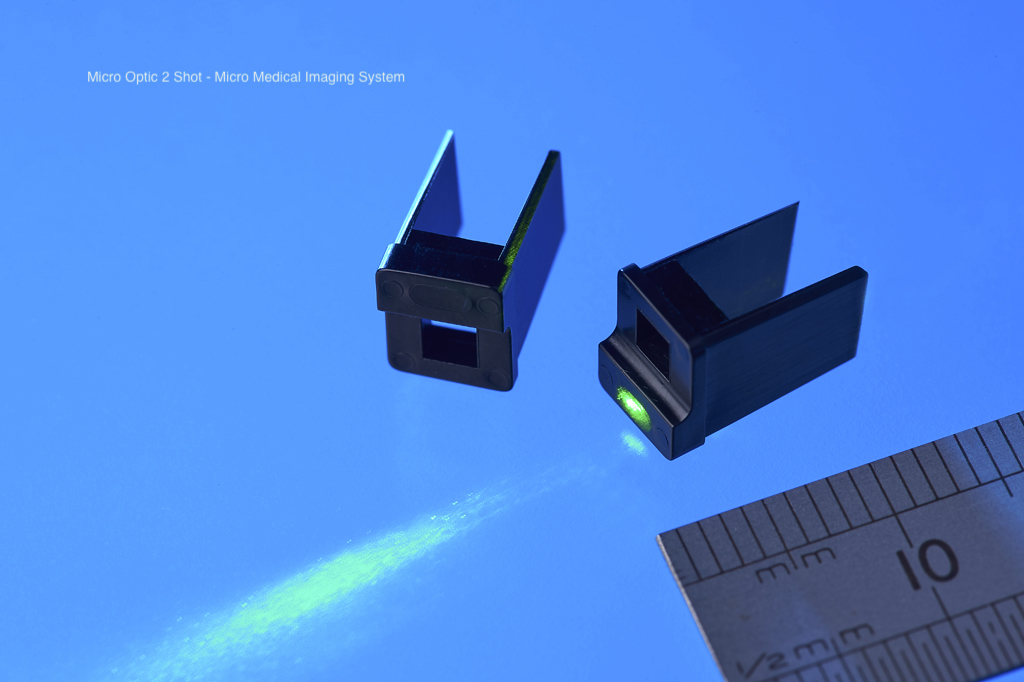

OPTICAL INSERTS

Micro Systems supplies optical-grade inserts for both conventional and micro molds. For select applications, we offer direct-machined, hardened stainless steel inserts with no manual polishing required—ensuring consistent surface quality, durability, and repeatability in high-precision molding.