Technologies

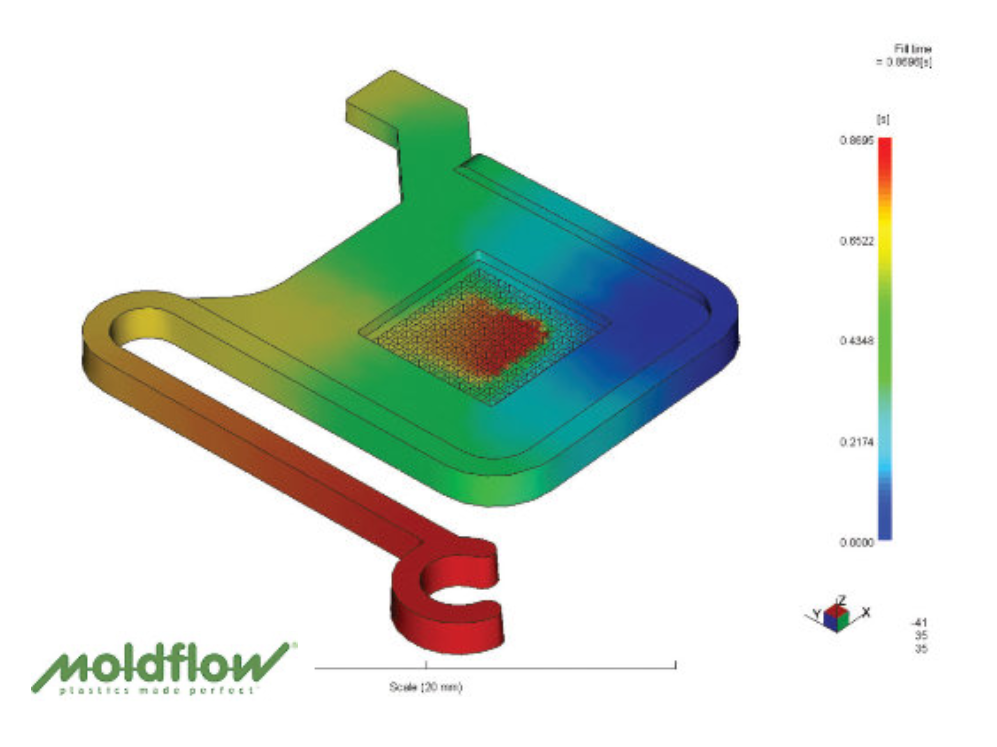

THE LATEST MOLD DESIGN SOFTWARES

We design in Siemens NX and 3D Moldflow, with continuous training to push design boundaries. Tech-enabled project management ensures on-time delivery and precision – every time.

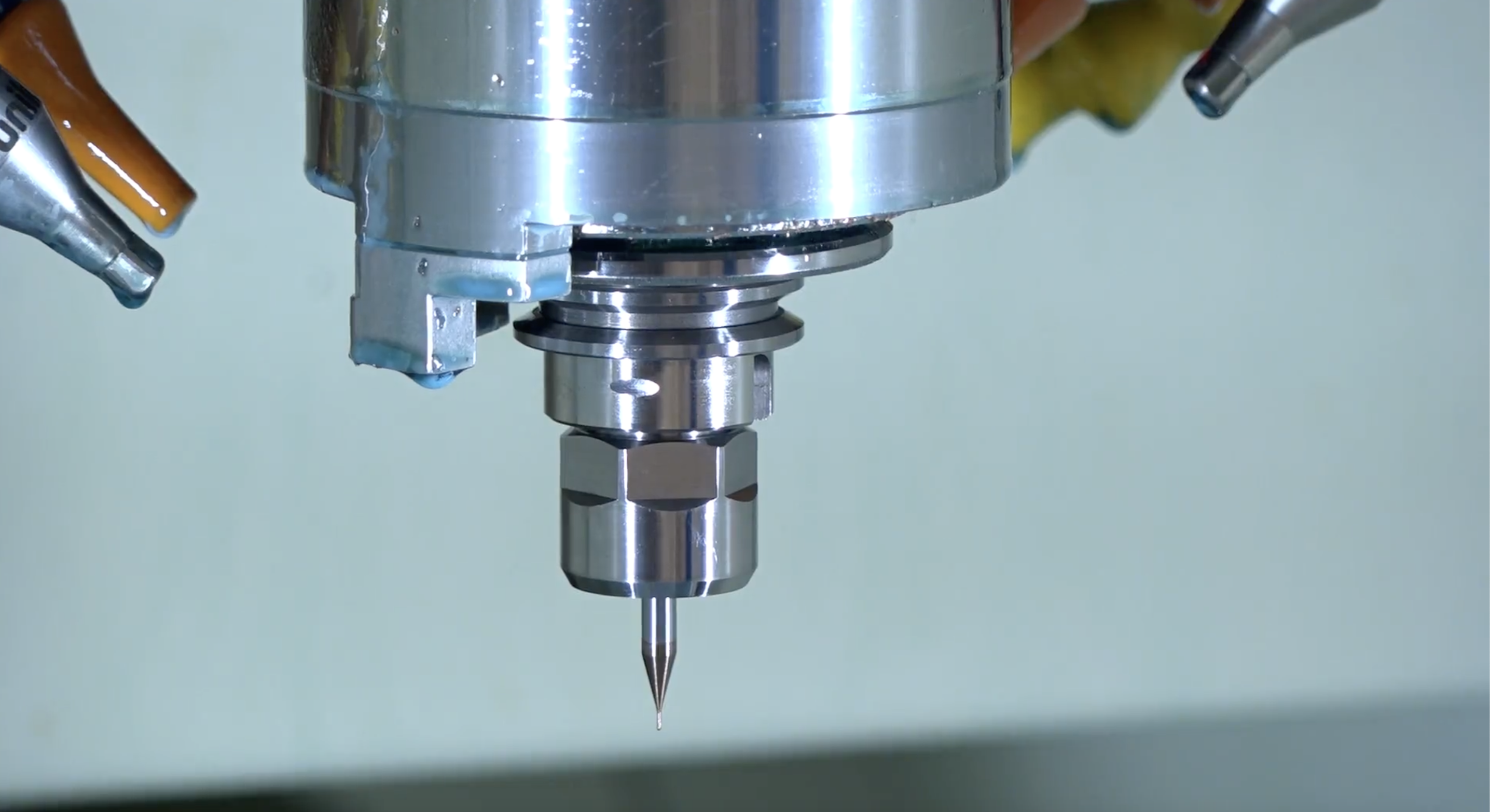

CONTINUOUS INVESTMENT IN MODERN MACHINERY

We only invest in advanced machinery for mold making and injection molding, equipping our facility with some of the most sophisticated systems in the industry.

WEDM machine: cut through hardened steel with a wire diameter of 30 microns (0.0013”), positional accuracy of 0.001mm (0.00004”)

5-Axis Micro Kern Milling: cut through hardened steel with a cutter diameter of 50 microns (0.002”), positional accuracy of 0.0005 mm (0.00002”).

Wittmann-Battenfeld Micropower molding machine: effective molding process for the smallest parts possible.

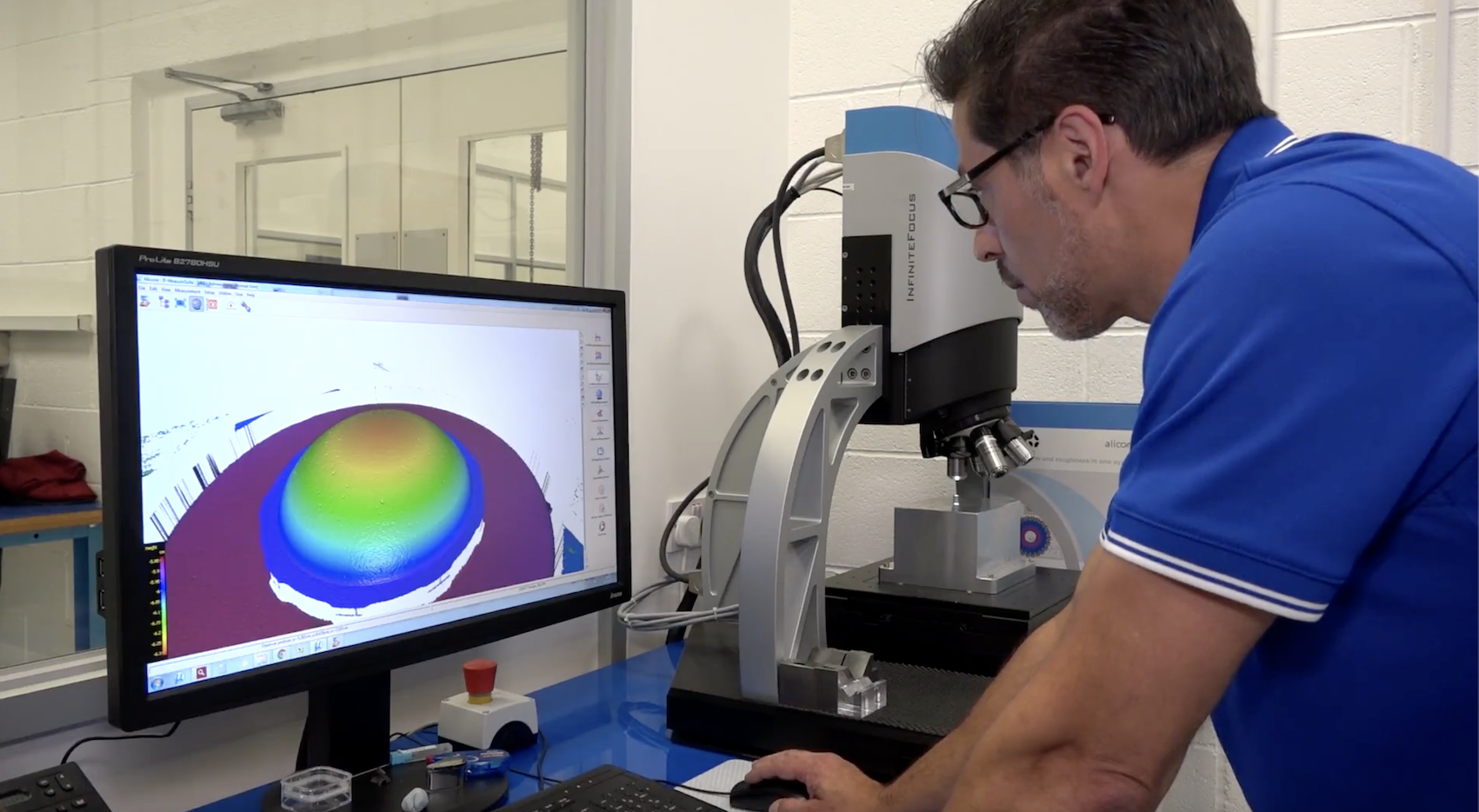

QUALITY CONTROL IN MANUFACTURING

With continuous investment in cutting-edge micro metrology, we reduce lead times, accelerate design updates, and lower costs. Our top metrology machines include:

Several CMM Vision and Probe Systems: deliver tolerances of 1μm.

GOM Software for 3D Measurement Data: used for shape and dimension analysis, 3D inspection and mesh processing for 3D point cloud and CAD data sets.

Digital Microscopes: scan 3D data with a maximum resolution of 10 nanometres.

Interferometer: scan 3D data with a maximum resolution of 0.2 manometer.

CTScan Computed Tomography: measure, analyze, inspect hidden defects and inner structures