Thermoplastic Material Selection for Reliable Drug Delivery Device Manufacturing

In drug delivery device manufacturing, material selection is critical not just for performance but for patient safety and reliability. Thermoplastics, with their ideal mechanical, chemical, and regulatory properties, are essential in devices like autoinjectors, inhalers, insulin pens, and infusion systems.

The Importance of Material Selection

For drug delivery devices, materials must withstand a range of stresses — from mechanical loads during use, to sterilization processes, to chemical exposure from active pharmaceutical ingredients (APIs). Selecting the right thermoplastic ensures not only robust manufacturing performance but also compliance with stringent medical standards, such as ISO 10993 and USP Class VI.

Poor material selection can lead to issues such as dimensional instability, drug interactions, or mechanical failure, any of which can compromise patient outcomes and trigger costly recalls.

Key Considerations in Thermoplastic Selection

- Biocompatibility and Regulatory Compliance

All materials in contact with the drug or patient must demonstrate proven biocompatibility. Commonly used thermoplastics such as cyclic olefin polymers (COPs), polycarbonate (PC), and medical-grade polypropylene (PP) are often selected for their track records in meeting regulatory benchmarks (ISO 10993, USP Class VI)

- Chemical Resistance

Devices often come into contact with aggressive solvents or drugs. For instance, polyoxymethylene (POM) and polyethylene (PE) offer good resistance to many pharmaceutical substances, but compatibility testing is essential.

- Mechanical Properties

The device must function reliably through its intended lifecycle. Materials like PC and PEEK (polyether ether ketone) offer excellent strength and dimensional stability, while elastomeric thermoplastics (TPEs) can be used for seals, grips, or actuation features requiring flexibility.

- Processability

Ease of molding is critical for production efficiency. Thermoplastics like ABS and medical-grade PP exhibit good flow properties and allow tight dimensional tolerances, which are essential for complex geometries in components like plungers or dose counters.

- Sterilisation Compatibility

Devices may undergo sterilization via gamma irradiation, ethylene oxide (EtO), or steam autoclaving. Materials must be stable under these conditions without degradation or discoloration. For instance, PPSU (polyphenylsulfone) is known for its high resistance to repeated steam sterilization.

Precision Molding for Enhanced Device Reliability

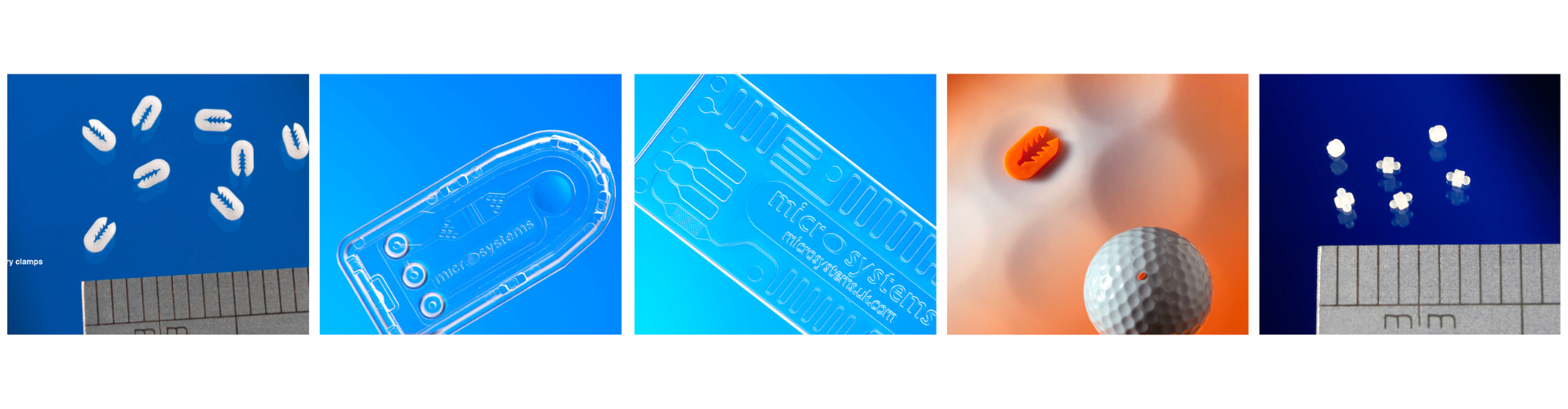

Precision injection molding is a cornerstone of manufacturing high-performance drug delivery systems. These devices often include tight-fitting, interlocking parts such as plungers, springs, dosage mechanisms, and safety locks. Tolerances are frequently in the micrometre range — and any deviation can lead to mechanical failure or dosing inaccuracies.

Precision molding ensures:

- Dimensional accuracy: Critical for components like needle shields and dosing cassettes where even a slight mismatch can impair function.

- Repeatability: Essential for multi-cavity tools and high-volume production, where every unit must meet identical performance standards.

- Cleanroom compatibility: Precision-molded components often meet ISO Class 7 or 8 cleanroom requirements to minimize particulate and microbial contamination.

- Improved sealing and assembly: High-precision parts reduce the need for post-mold adjustments or overengineering, improving device reliability and reducing assembly line errors.

By leveraging high-precision molding technologies — including electric molding machines, in-mold sensors, and cavity pressure monitoring — manufacturers can produce components that meet exact specifications consistently, which is vital for ensuring patient safety and regulatory compliance.

Material Trends in Drug Delivery Devices

With the rise of self-administration and connected health technologies, design trends are shifting toward lightweight, ergonomic, and smart-enabled devices. Thermoplastics enable integration of features such as windows for dose visibility, tamper-evident closures, and even embedded electronics. Additionally, sustainability is becoming a growing concern. Bio-based and recyclable polymers are beginning to emerge as viable alternatives, especially for single-use components.

Partnering with Micro Systems for Material and Manufacturing Excellence

As a trusted injection molding specialist, we work closely with medical device OEMs to ensure the optimal thermoplastic is selected early in the development cycle. This collaborative approach allows for smoother design-for-manufacture transitions, validation processes, and scalability.

We offer:

- Expertise in processing medical-grade thermoplastics

- ISO Class 7 and 8 Cleanroom molding capabilities

- Support with regulatory documentation and material traceability – FAT, IQ, OQ, PQ, Mold testing, Validation

- Small scale to mass production

Thermoplastic selection is a foundational decision in drug delivery device manufacturing, with far-reaching implications on safety, performance, and regulatory success. When combined with high-precision injection molding, it ensures that each device functions reliably and consistently — from the production floor to the patient’s hand. At Micro Systems, our commitment to quality and innovation ensures that every component we mold supports the ultimate goal — improving patient care through reliable, precision-engineered medical devices.