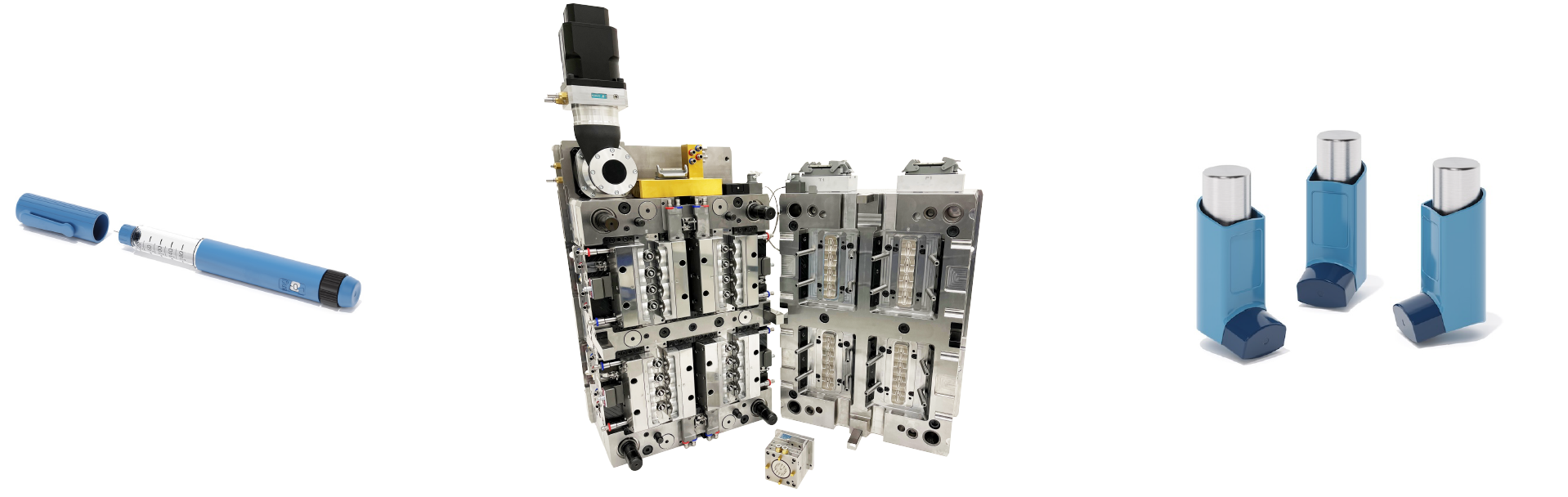

Pulmonary drug delivery systems (PDDS) have revolutionized the treatment of respiratory diseases by enabling direct deposition of therapeutic agents into the lungs. The efficacy of these devices is significantly influenced by the precision and quality of their components, which are predominantly manufactured using medical molding techniques.

Precision in device design and functionality

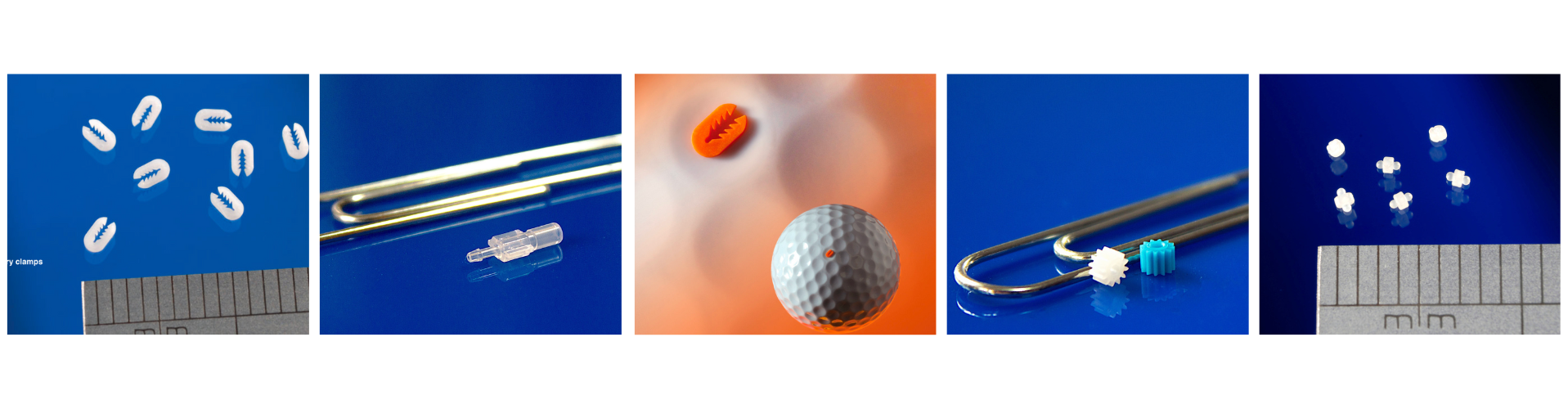

The performance of PDDS, such as metered-dose inhalers (MDIs), dry powder inhalers (DPIs), and nebulizers, is intricately linked to the precision of their molded components. For instance, the actuator’s geometry in an MDI directly influences the spray pattern and particle size distribution, which are critical for effective drug deposition in the lungs. Advancements in micro molding have enabled the production of components with micron-level tolerances, facilitating the development of devices that can deliver precise doses of medication. This precision is particularly crucial when designing devices for targeted therapies, such as those delivering biologics or mRNA-based treatments. Microfabrication techniques have been highlighted for their advantages in achieving unprecedented control over particle geometric design for drug delivery (1).

Material selection and biocompatibility

The materials used in medical molding must not only meet mechanical and dimensional specifications but also adhere to biocompatibility standards. Common materials include medical-grade plastics like polycarbonate and polypropylene, as well as silicones, which are often used for components requiring flexibility and durability. These materials are selected based on their ability to withstand sterilization processes and their compatibility with the human body, ensuring patient safety and device reliability. A comprehensive overview of biomaterials emphasizes their pivotal role in drug delivery, classifying them in terms of their biobased, biodegradable, and biocompatible nature, and highlighting their characteristics and advantages (1).

Manufacturing standards and quality assurance

Manufacturers of PDDS must comply with rigorous quality standards to ensure the safety and efficacy of their products. This includes adherence to ISO 13485 for medical device quality management systems and ISO 14644-1 for cleanroom environments, which are essential for maintaining the integrity of molded components during production. Implementing stringent quality assurance protocols throughout the manufacturing process helps in identifying and mitigating potential defects, thereby enhancing the overall performance and safety of the final device. Research in nanotechnology focuses on developing nanoscale materials for targeted drug delivery, imaging, and sensing applications, which are integral to the advancement of PDDS (10).

Advancements in micro and nano molding

The evolution of micro and nano molding techniques has significantly impacted the design and functionality of PDDS. These advanced molding processes allow for the fabrication of components with intricate geometries and precise dimensions, which are essential for the development of next-generation inhalation devices. For example, micro-molded components can facilitate the creation of microfluidic systems for drug delivery, enabling controlled release and targeted therapy. Additionally, nano-molding techniques are being explored for the production of nanoparticle-based drug delivery systems, which can offer enhanced drug stability and bioavailability (7).

Future directions in pulmonary drug delivery

The future of PDDS is poised for significant advancements, driven by innovations in medical molding technologies. Emerging trends include the development of smart inhalers equipped with digital sensors to monitor usage patterns and adherence, as well as the integration of artificial intelligence to optimize drug delivery strategies. Furthermore, the exploration of biodegradable and eco-friendly materials in molding processes aligns with the growing emphasis on sustainability in medical device manufacturing. These developments aim to enhance the performance, patient experience, and environmental footprint of PDDS (8).

Medical molding plays a pivotal role in the development of advanced pulmonary drug delivery devices by enabling the production of precise, biocompatible, and reliable components. As the demand for effective respiratory therapies continues to rise, the evolution of molding technologies will be instrumental in shaping the future of pulmonary medicine, ensuring that patients receive optimal care through innovative and efficient drug delivery systems.

References

- Garcia, A. (2012). Microfabricated Engineered Particle Systems for Respiratory Drug Delivery and Other Pharmaceutical Applications. Journal of Drug Delivery, 2012, Article ID 941243. https://pmc.ncbi.nlm.nih.gov/articles/PMC3307013/

- Trucillo, P. (2024). Biomaterials for Drug Delivery and Human Applications. Biomaterials Science, 2024. https://pmc.ncbi.nlm.nih.gov/articles/PMC10817481/

- Bock, S. (2022). Additive Manufacturing in Respiratory Sciences. Advanced Drug Delivery Reviews, 2022. https://www.sciencedirect.com/science/article/pii/S0169409X22002319

- Sadeghi, I. (2022). Micromolding of Thermoplastic Polymers for Direct Drug Delivery Applications. Small Methods, 2022, 6(2), 2200232. https://onlinelibrary.wiley.com/doi/full/10.1002/smtd.202200232

- Clark, A. R. (2022). Half a Century of Technological Advances in Pulmonary Drug Delivery. Frontiers in Drug Delivery, 2022, 3, 871147. https://www.frontiersin.org/articles/10.3389/fddev.2022.871147/full

- Trucillo, P. (2024). Innovations in Processing, Advancements, and Challenges in Nanotechnology for Drug Delivery. Nanotechnology Reviews, 2024. https://journals.sagepub.com/doi/10.1177/25165984241256234

- Sadeghi, I. (2022). Micromolding of Thermoplastic Polymers for Direct Drug Delivery Applications. Small Methods, 2022, 6(2), 2200232. https://onlinelibrary.wiley.com/doi/full/10.1002/smtd.202200232

- Bock, S. (2022). Additive Manufacturing in Respiratory Sciences. Advanced Drug Delivery Reviews, 2022. https://www.sciencedirect.com/science/article/pii/S0169409X22002319

- Clark, A. R. (2022). Half a Century of Technological Advances in Pulmonary Drug Delivery. Frontiers in Drug Delivery, 2022, 3, 871147. https://www.frontiersin.org/articles/10.3389/fddev.2022.871147/full

- Trucillo, P. (2024). Innovations in Processing, Advancements, and Challenges in Nanotechnology for Drug Delivery. Nanotechnology Reviews, 2024. https://journals.sagepub.com/doi/10.1177/25165984241256234